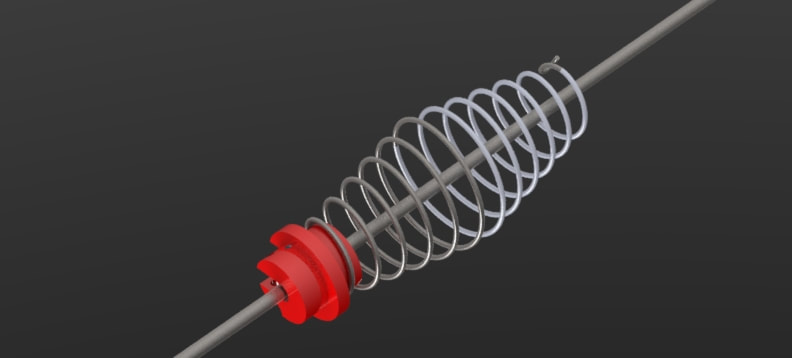

A NEW BARREL SPRING SYSTEM CONSIDERED A MAJOR MODIFICATION IN ALMOST ALL JURISDICTIONS

WE REQUIRE TESTING WITH 375-LBS OF WEIGHT

Richardson Safety Barrel Spring Sets for 6 miles per hour with a 250-lb rider

Estimated 10 Barrel Springs, 10 Barrel Spring Spacers, and Bumper Spacer …………….. $1,700

Richardson Safety Barrel Spring Sets for 12 miles per hour with a 250-lb rider

Minimum Barrel Spring System (BSS) price 12 miles per hour

Estimated 18 Barrel Springs, 18 Barrel Spring Spacers, and Bumper Spacer …………….. $3,200

Richardson Safety Barrel Spring Sets for 18 miles per hour with a 250-lb rider

Minimum Barrel Spring System (BSS) price 18 miles per hour

Estimated 27 Barrel Springs, 27 Barrel Spring Spacers, and Bumper Spacer …………….. $4,100

Richardson Safety Barrel Spring Sets for 24 miles per hour with a 250-lb rider

Minimum Barrel Spring System (BSS) price 24 miles per hour

Estimated 36 Barrel Springs, 36 Barrel Spring Spacers, and Bumper Spacer …………….. $5,400

M. Troy Richardson of Momentum Engineering, LLC, will be available to consult for a $150 per hour to be paid by the customer for a Barrel spring system design. Momentum Engineering, LLC will travel if Mr. Richardson is requested to help plan a Zipline build and install; ordinary travel expenses must be discussed, including business airfare for Momentum Engineering, LLC staff.

[email protected]

Nothing contained ON THIS PAGE OR THE WEBSITE may be considered engineering and or zipline systems advice. No relationship is established herein; we are not liable for your use of any information within this document. No information should be relied upon unless a jurisdictional Professional Engineer has proven the brake system. Best practice is to have a Professional Engineer run the calculations for your system and stamp the new brake system. The system will then require to be service proven and or fail-safe. Our testing is not guaranteed to be accurate, complete, or current unless all variables and scenarios are verified and evaluated. If you need advice, please consult a licensed professional engineer, a qualified, certified, and insured designer, and or an accredited zipline expert in your state or jurisdiction who has tested the zip line braking system.

WE REQUIRE TESTING WITH 375-LBS OF WEIGHT

Richardson Safety Barrel Spring Sets for 6 miles per hour with a 250-lb rider

Estimated 10 Barrel Springs, 10 Barrel Spring Spacers, and Bumper Spacer …………….. $1,700

Richardson Safety Barrel Spring Sets for 12 miles per hour with a 250-lb rider

Minimum Barrel Spring System (BSS) price 12 miles per hour

Estimated 18 Barrel Springs, 18 Barrel Spring Spacers, and Bumper Spacer …………….. $3,200

Richardson Safety Barrel Spring Sets for 18 miles per hour with a 250-lb rider

Minimum Barrel Spring System (BSS) price 18 miles per hour

Estimated 27 Barrel Springs, 27 Barrel Spring Spacers, and Bumper Spacer …………….. $4,100

Richardson Safety Barrel Spring Sets for 24 miles per hour with a 250-lb rider

Minimum Barrel Spring System (BSS) price 24 miles per hour

Estimated 36 Barrel Springs, 36 Barrel Spring Spacers, and Bumper Spacer …………….. $5,400

M. Troy Richardson of Momentum Engineering, LLC, will be available to consult for a $150 per hour to be paid by the customer for a Barrel spring system design. Momentum Engineering, LLC will travel if Mr. Richardson is requested to help plan a Zipline build and install; ordinary travel expenses must be discussed, including business airfare for Momentum Engineering, LLC staff.

[email protected]

Nothing contained ON THIS PAGE OR THE WEBSITE may be considered engineering and or zipline systems advice. No relationship is established herein; we are not liable for your use of any information within this document. No information should be relied upon unless a jurisdictional Professional Engineer has proven the brake system. Best practice is to have a Professional Engineer run the calculations for your system and stamp the new brake system. The system will then require to be service proven and or fail-safe. Our testing is not guaranteed to be accurate, complete, or current unless all variables and scenarios are verified and evaluated. If you need advice, please consult a licensed professional engineer, a qualified, certified, and insured designer, and or an accredited zipline expert in your state or jurisdiction who has tested the zip line braking system.